Four decades of running down the physical economy in favour of building up speculative bubbles and service economies has left most of the world illequipped to tackle a global pandemic which was not unforeseen.

The late American economist Lyndon LaRouche commissioned a study in 1973 which warned that replacing industrial policy with zero-growth targets would lead to the resurgence of old plagues and the occurrence of new diseases and pandemics. America’s Central Intelligence Agency (CIA) issued its own study in January 2000, warning that 22 well-known diseases had re-emerged since 1973, 30 previously unknown diseases had been identified, and acute lower respiratory infections, including pneumonia and influenza, were peaking. This was rightly put down to the lack of scientific advances and increasing globalisation.

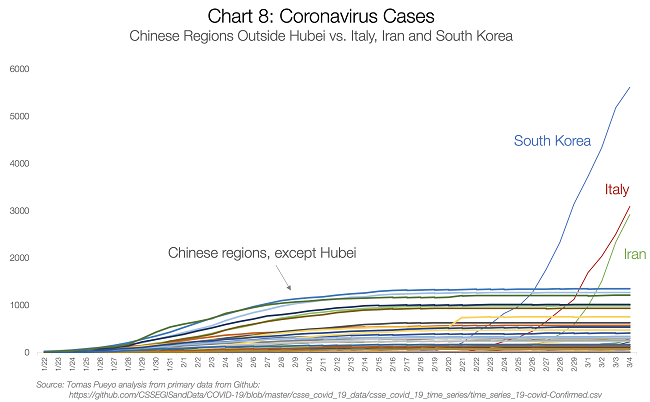

Following the 2008 global financial crisis, China realised that financial speculation had suffocated the real economy and launched an economic revival to which it attempted to recruit the world. For the most part it was not taken up, however, so China’s recent stunning growth is a deviation from the trend of global economic decline. The response of productive economies such as China and South Korea to today’s novel coronavirus pandemic shows that nations which have resisted or reversed the post-industrial policies of the last forty years stand a dramatically better chance of surviving.

Even normally anti-China scribe David LlewellynSmith from MacroBusiness acknowledged this in a 11 March article, “China saves its people as democracies slaughter theirs”, which declared that “it is impossible to miss the diametric opposite responses of East and West to the pandemic” (p. 3). With a strong productive base the economy can be rapidly mobilised to provide necessary requirements.

Llewellyn-Smith’s headline rings true in the United Kingdom’s response to the crisis. The Boris Johnson government briefly toyed with a proposal to allow up to 60 per cent of Britons to contract the virus, which it hoped would lead to so-called herd immunity. An op-ed in China’s Global Times describing the proposal as stemming from a “laissez-faire mindset”, quoted Seema Yasmin, a clinical assistant professor at Stanford University, who said the proposal would equate to “39.6 million infected, 2 million critically ill and 277,000 deaths”. On 3 March the assistant editor at London’s Daily Telegraph, Jeremy Warner, made clear that this is not some unintended consequence: “Not to put too fine a point on it, from an entirely disinterested economic perspective, the COVID-19 might even prove mildly beneficial in the long term by disproportionately culling elderly dependents.”

On the other hand, China’s action to lock down Wuhan in Hubei Province limited the spread of the disease, enabling certain regions of the country to keep producing. Regions that were affected did not grind to a halt and recovered more swiftly. Indeed, China is reportedly now producing over 100 million surgical masks, 1.7 million N95 respirator masks, 1.2 million coronavirus infection test kits and 350,000 antibody test kits per day. A testing kit that delivers results in 15 minutes, requiring only one drop of blood from the patient, has been developed.

China has already been able to close the 14 temporary hospitals it built in one month in Wuhan, which added a capacity of 16,000 hospital beds. It demonstrated that “flattening the curve”, a tactic to slow the spread of the virus through lockdown and social isolation, whilst important to stop the hospital system getting swamped, is not enough alone. It is critical to build up additional healthcare facilities and capabilities.

The Chinese economy turned on a dime to a degree that Beijing was able to send a team of experts and equipment to Italy. China has sold 10,000 ventilator machines to Italy, along with 2 million face masks, 20,000 protective suits and 50,000 test kits. (At the beginning of the year, Italy had sent protective masks to China when it faced shortages.) China also sent medical personnel to Iran, and scientists recently held a videoconference with health officials from the 17 Central and East European countries.

Plans by Italy’s Lombardy region to build an emergency hospital on the premises of the Milan Trade Fair within six days have been stymied for the moment after authorities were unable to secure the necessary equipment. Like other governments under the EU bureaucracy, Italy has procedures mandating that all government purchases must be awarded by tender to the cheapest offer. The highpriced ventilators readily available on the market did not fit the requirements. A shipment of face masks is similarly awaiting bureaucratic authorisation.

Production of most such equipment has been outsourced, but companies that do have the capability to produce ventilators are scaling up production. One of only four manufacturers in Europe, Siare Engineering in Bologna will aim to triple or quadruple its production of ventilators by hiring 25 technicians from the Army, to be trained in 3-4 days.

Faced with the gravity of the crisis, many US leaders are swinging back to basics, demanding action to restore economic capacity along with research and development capabilities. New York Governor Andrew Cuomo called on President Trump to mobilise the military to fight the emergency. “At this point, our best hope is to utilise the Army Corps of Engineers to leverage its expertise, equipment and people-power to retrofit and equip existing facilities—like military bases or college dormitories—to serve as temporary medical centres”, he wrote in the 15 March New York Times. The Corps, which built hospitals during the 2014 West African Ebola epidemic, “have the equipment, the manpower, the resources”, he told a press conference. “The Army Corps of Engineers is amazing—I’ve worked with them.”

Prominent epidemiologists have said military branches can be trained and deployed rapidly. Michael Osterholm, the US expert who led the response to the 2003 SARS and 2012 MERS coronavirus outbreaks, has called for a Manhattan Project approach to biomedical sciences and public health, funded to war-time levels, which would include whole sections of the Defence Department. It is not too late for large-scale testing in the United States to make a significant difference, said Eric Feigl-Ding, a senior fellow at the Federation of American Scientists, but, “It’s like a battlefield, we need to get to the front lines. We can’t get there a week or two after the fact.”

Likewise for Australia. Finally the government has made a step in the direction of organising the physical requirements to deal with the emergency. As part of a $2.4 billion health package the government has commenced mapping local manufacturers that could produce hazmat suits, surgical gowns, gloves, masks, hand sanitiser and various other supplies, negotiating support necessary for them to ramp up production. Protective equipment manufacturer Med-Con near Shepparton in Victoria will receive assistance from Australian Defence Force personnel to increase production by up to ten times.

Meanwhile, our intrepid scientists continue to advance. While the first vaccine trial has commenced in the USA, University of Queensland researchers have settled on a candidate vaccine which will now move into the testing phase, and UQ’s Centre for Clinical Research and its collaborators around the country are developing a treatment based on trials of HIV and malaria drugs, which killed the virus in test-tube trials. The facility needs $750,000 to develop the drug and around three months to roll it out.

By Elisa Barwick, Australian Alert Service 18 March 2020